Featured

UBM formation for aluminum electrodes on wafers

Plating process and plating equipment

TORYZA EL PROCESS, TORYZA EL SYSTEM

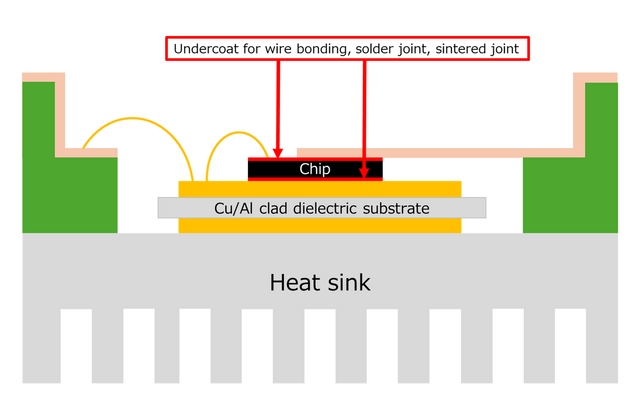

Power semiconductors are used in a variety of applications, including industrial equipment, solar power generation, electric vehicles, communications equipment, and energy conversion devices. In power modules, an electroless plating is used as an under barrier metal (UBM) to bond aluminum electrodes on a chip and package terminals by soldering or silver sintering (① in the figure), or to bond the electrodes and copper/aluminum clad dielectric substrates by soldering or silver sintering (② in the figure).

Although electroless Ni/Au plating and electroless Ni/Pd/Au plating are widely used for UBM (Under Barrier Metal), conventional processes have problems such as localized corrosion of aluminum electrodes, poor plating appearance, and poor adhesion. In recent years, as power semiconductors have become more voltage and current intensive, electroless plating films are required to have higher heat resistance.

To solve these problems, we have developed the "TORYZA EL PROCESS", a plating process for forming UBM for aluminum electrodes on wafers.

Product features, specifications

Okuno has been developing and manufacturing surface treatment and plating chemicals for over 60 years. As we expand our product line for the semiconductor industry, we believe it is important to offer a total solution of plating chemicals, surface treatment processes and equipment for this field. Therefore, Okuno has launched a new brand for semiconductor back-end processes, TORYZA.

TORYZA EL PROCESS is a plating process for forming UBM on aluminum electrodes of wafers by electroless nickel plating after zincate treatment. We offer the best solution, not only chemicals but also the automatic plating equipment for UBM formation, "TORYZA EL SYSTEM". TORYZA EL SYSTEM is designed and developed in cooperation with an equipment manufacturer based on the know-how we have acquired as a plating chemical supplier.