Electroless copper plating process for LCP

TOP LECS PROCESS

Since 2020, the Fifth-Generation mobile communication system has been pushed forward following 4G also in Japan. In the era, ultra-high speed communication can be realized, also we can control robots and consumer electronics from distance areas by super low latency. Furthermore, it becomes possible to connect many computers, smartphones and various devices simultaneously.

Now, high-frequency-compatible substrates with low dielectric constant such as LCP (liquid crystal polymer) and fluoropolymer are attracting attention. Especially, the use of LCP is sharply increasing for 5G and millimeter wave applications from the electrical characteristics in high-frequency range, low water absorption and high dimensional stability.

To solve the adhesion problems of the copper plating on LCP, we have developed a new process by the combination of a surface modification step and a plating step.

Product features, specifications

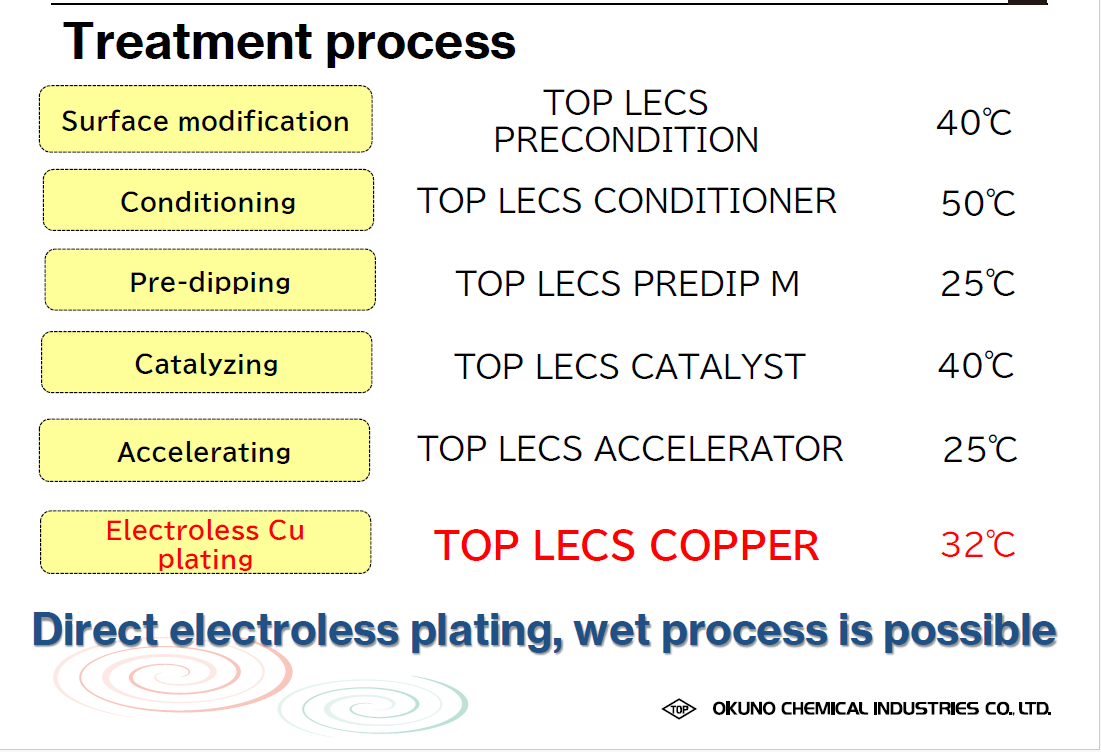

TOP LECS PROCESS is an electroless copper plating process developed exclusive for liquid crystal polymer. This process is a direct plating method without using copper foils. Generally, dry plating process by vapor deposition, sputtering, and other methods requires large-scale and expensive equipment. However, TOP LECS PROCESS enables to form patterns on LCP films directly. This process is developed by a combination of a surface modification step and a plating step. In the surface modification step, the surface layers of LCP will be finely modified, and in the next step, the plating films with low film stress will be finely formed. Even after applying thermal stress at 150℃ for 72 hours, high adhesion strength over 6 N/cm can be ensured without increasing surface roughness.

This process is applicable to roll-to-roll plating system and semi-additive process. We can conduct all of the steps by wet process, and it will contribute to the improvement of productivity and fine pattern formation.

Electroless copper plating process for LCP

This process is developed by a combination of a surface modification step and a plating step. In the surface modification step, the surface layers of LCP will be finely modified, and in the next step, the plating films with low film stress will be finely formed. Even after applying thermal stress at 150℃ for 72 hours, high adhesion strength over 6 N/cm can be ensured without increasing surface roughness.