Process for metallic finishing by plating on plastic

TOP DuNC PROCESS

The technology for plating on plastic was developed in the advent of ABS resin. In the past, zinc die cast or other metals were used for car parts that required decorative finishing. However, the materials has changed from metals to plastic in order to car weight reduction, and the plating on plastic technology enables to decorate plastic and obtain metallic appearances.

Plastic is a material that can be easily molded and expand the freedom of product designs. Plated plastic has been widely discovered in our daily life, for example, cars, faucets, bath and kitchen items as well as consumer appliances. Plating on plastic enables highly elegant appearances and luxurious finishing that can’t be obtained by painting.

The technology contributes to the weight reduction of car body, and is expected to promote the sustainable development for carbon neutral society.

Product features, specifications

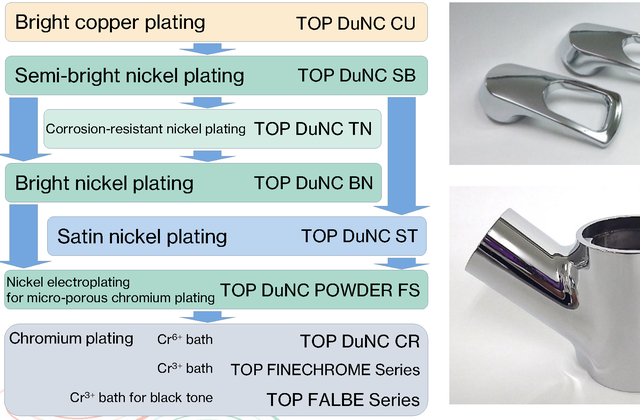

We have developed TOP DuNC PROCESS as a process for multi-layer plating on molded plastic parts. We provide a multi-layer plating process for copper, semi-bright nickel, bright nickel, chromium plating in order to increase high adhesion on plastic, to give plastic scratch resistance and to achieve rich and luxurious appearances. Besides, you can choose your preference colors and tones from silver to dark colors as well as from shiny to matte tones.

The technology of plating on plastic is very important in product design to obtain high class appearances. We have developed the new plating process to pursue high-level film properties, thickness uniformity and high corrosion resistance. We can provide a total solution for plating on plastic to meet your requirements from every angle.

Process for metallic finishing by plating on plastic

We provide a multi-layer plating process for copper, semi-bright nickel, bright nickel, chromium plating in order to increase high adhesion on plastic, to give plastic scratch resistance and to achieve rich and luxurious appearances. Besides, you can choose your preference colors and tones from silver to dark colors as well as from shiny to matte tones.