Electroless copper plating process for horizontal plating systems

OPC H-TEC PROCESS NEX

Printed wiring boards (PWBs) are widely used in any of industrial equipment, consumer electronics and home appliances. Conventionally, thinner, higher-density and higher-performance PWBs have been requested. Now, there has been additional demands in the improvements of productivity and working environments. Thus, continuous horizontal copper platers have prevailed for the electroless copper plating to PWBs. Horizontal plating systems have many advantages, for example, saving time and labor cost for racking as well as improving working environments by using closed systems. But the horizontal platers have a problem that needs a long time for machine maintenance.

Product features, specifications

If continuous horizontal systems are used for electroless copper plating, plating defects or conveyance roller traces, which are mainly caused by palladium-related aggregations, are often discovered on PWBs after the plating.

To solve such problems regarding horizontal conveyance systems, we have developed an exclusive electroless copper plating process, OPC FLET PROCESS NEX. For the new process, we have developed a new pre-dipping solution that can inhibit roller traces by palladium-related aggregations, and can reduce the maintenance time for conveyance rollers.

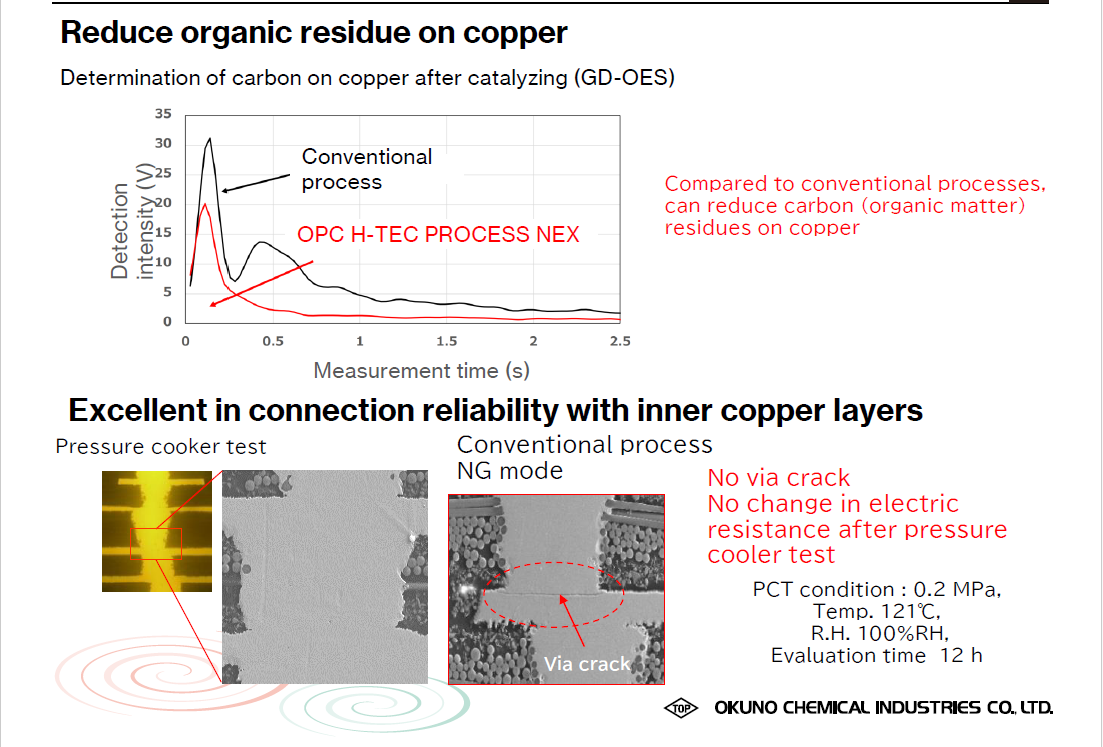

Also, we have succeeded to increase the initial reactivity of the electroless copper plating solution in order to prevent the blisters on low-profile flexible areas in flexible-rigid PWBs. Also, OPC FLET PROCESS NEX enables to increase the connection reliability between copper plating films and inner copper layers.

Electroless copper plating process for horizontal plating systems

OPC H-TEC PROCESS NEX, is developed especially for continuous horizontal copper platers. The plating process enables to increase the connection reliability between copper plating films and inner copper layers.