Featured

Electroless copper plating process that provides high plating adhesion to glass substrates

PLOPX

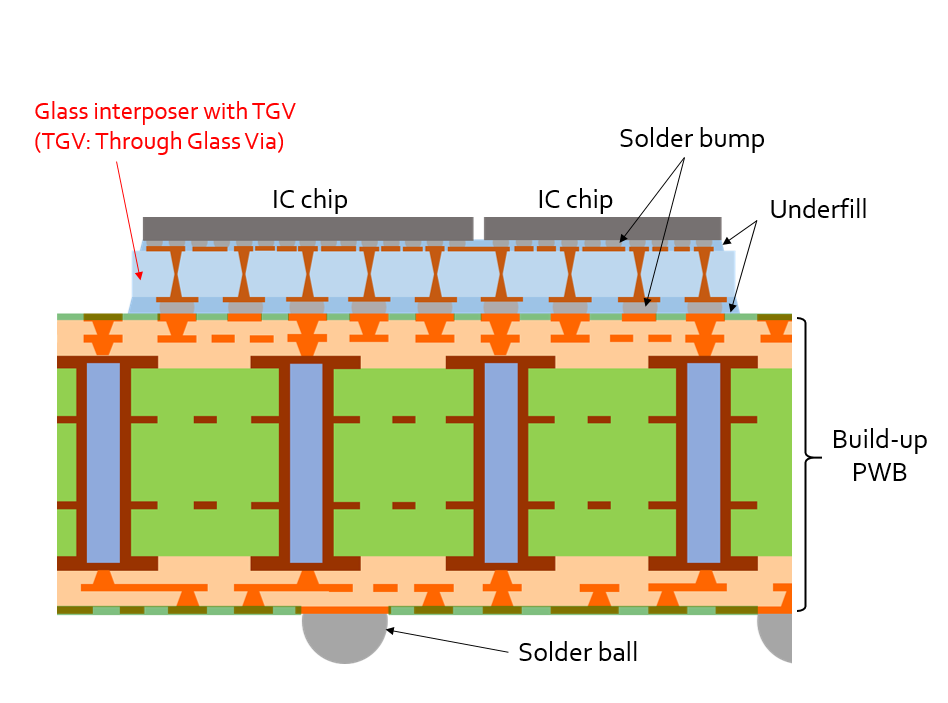

Glass is excellent in signal transmission property owing to its outstanding surface smoothness and electric insulation. Thus, glass has been drawing intense research as an interposer substrate for 2.5D package integration. In previous studies, sputtering, sol-gel and various methods have been studied as a process used in precoating to increase adhesion on glass.

We have developed an electroless copper plating process that can achieve high adhesion on glass substrates. In this new process which is named PLOPX, a metal oxide film layer is formed by Liquid Phase Deposition (LPD) method to increase adhesion wherein all procedure can be achieved by wet method.

Product features, specifications

In collaboration with Panasonic Environmental Systems & Engineering Co., Ltd., we have developed PLOPX, an electroless copper plating process that can achieve high adhesion on glass substrates. Nowadays, glass is one of the candidate materials as an interposer for 2.5D integrated circuit (2.5D IC). By forming the metal oxide layers with high smoothness from LPD (liquid phase deposition) method, we can achieve high adhesion and heat resistance without losing the features of glass.

Furthermore, due to all procedure in PLOPX can be conducted by wet process, high aspect ratio of through-glass via (TGV) substrates can be treated. PLOPX is expected as the new process for high-speed communication systems for 5G and 6G mobile communications.